What is the Best Grease for Polyurethane Suspension Bushings?

Whether it’s a rock crawler, weekend track machine, or a daily driver that can take corners like it’s on rails, polyurethane bushings are great for performance and longevity, but they do require some infrequent maintenance to keep them quiet and in perfect working order. This can be done in your own garage or by the shop but one of the first decisions you have to make is, “What grease do I use?” The folks at DST will attempt to answer that question below.

Table of Contents

What Grease Should I Use For Polyurethane Bushings?

This is one of the first questions you need to answer and it can be a little confusing. Everyone has an opinion and there are several lubricant options, and honestly, any of them will “work” in the sense that all grease will lubricate a polyurethane bushing in some respect. That said, not all grease is created equal and when it comes to poly bushings you want two basic things: high adhesion (stickiness) and low coefficient of friction (reduced friction). Since the grease on these bushings is not in a sealed system it can be squeezed, melted, or washed out given the right circumstances so choosing the right grease is important. We will show you some of the best options when it comes to lubricant for polyurethane.

Silicone vs Lithium (PTFE and Moly)

As the two most common types of lubricants for polyurethane bushings we will take a look at what makes them tick.

Silicone Based Lubricant

Silicone lubricant is very tacky and sticks to just about everything, from polyurethane, to zinc coated sleeves, to bare skin. This is the main reason many poly bushing manufacturers use a silicone base in their grease. A common additive to that base is PTFE (polytetrafluoroethylene) since it lowers friction and is completely waterproof, both things you want in a lubricant. PTFE does not mix well with oil, or any other liquid, but it holds silicone lubricant to polyurethane bushings and sleeves very well, making a tough, sticky combination.

Lithium Based Grease

Lithium based grease adheres to metal very well, has a high heat tolerance, and is water resistant making it another possibility for use with polyurethane bushings. These lubricating agents are basically oil mixed with lithium soap, usually with several additives. One of the additives commonly used in lithium grease is Moly (Molybdenum Disulfide) which is actually a common additive to PTFE compounds. Lithium grease is usually thinner and it isn’t quite as tacky as silicone, which are significant downsides, but it is still a reliable option for any daily driver.

Maunfacturer Grease

Most aftermarket bushing manufacturers provide their own special blend of grease for their bushings and many include this in the box with the part. We here at DST suggest that you use the manufacturer’s grease since they are often formulated to work with the specs of that particular blend of polyurethane. If the manufacturer offers grease then this is likely going to be your best option since they have an interest in making sure the bushings you bought function quietly and correctly. You can purchase more of this grease separately when maintenance time comes around.

Other Suitable Lubricants

Marine Grease

This style of grease is usually a lithium based grease that has many things in common with the manufacturer grease such as water repellent properties and tackiness. All the things that make this grease good for it’s designed purpose of handling applications around water also make it a good candidate for polyurethane bushing grease. That said, this grease is usually thinner than the manufacturer’s silicone based lubricant.

Heavy Duty Grease

This is grease that is meant for heavy equipment and is very resistant cold, heat, and the elements. It is usually a lithium based grease with additives that make it tougher and more tacky so when it’s put under extreme pressure it stays put. This is a good option if for some reason you can’t get more of the manufacturer’s grease or would rather use a lithium based lubricant.

Not So Suitable Lubricants

Motor Oil

Even quality 80W motor oil is not going to stick to your polyurehtane bushings for very long. It works great in a closed system like your engine where metal on metal parts are creating enormous amounts of friction and heat, but polyurethane bushings are not sealed and when your suspension travels whatever lubricant is between the bushing and the metal is going to be exposed to the elements. Motor oil has amazing lubrication properties, it just doesn’t have a chance to shine in the case of poly suspension bushings.

Spray Lubricant

This is commonly used as a quick fix for squeaky bushings, but it has such a short effective lifespan that if you plan on it being a long-term solution just buy a case at Costco and keep it in the trunk. Whatever the brand, whatever the components a spray lubricant isn’t a good substitute for the manufacturer’s silicone grease or even one of the other options.

Used Motor Oil From A Bucket In The Barn

Don’t. Just… don’t.

Testing the Grease

Time to put on our lab coats and saftey goggles and see what this grease can do.

The Oven Test

Just Like Mother Used To Make

Again, the upper limit heat range of this grease (some as high as 550 degrees) is not an every day occurrence but it’s nice to be able to see with your own eyes how the grease is affected by heat. So we applied the same manufacturer grease to those poly bushings, popped them into the DST cookie maker, and slowly turned up the heat. The bushing manufacturer advised against heating the bushing above 200 degrees for long so we set the heat and waited 5 hours. Here are the results.

Results

Yeah, nothing changed besides the fact that we had to air out the room afterwards. These lubricants can withstand a LOT of heat, in most cases more than the bushings themselves. If you use one of these lubricants and notice that it is dripping from one of your bushings then you may want to call the fire department to come put out your vehicle.

The Minor Adhesion Test

As we said before, this grease needs to be very sticky and what better way to test this than trying to wipe it off. If you’ve had any dealings with the manufacturer’s silicone based grease then you know that if you don’t wear gloves it will be with you for a while. This is what you want from your bushing grease so we’ll take a look at the difference between the manufacturer’s silicone grease and a marine grade lithium grease when you just try to wipe them away with a shop towel.

Manufacturer Grease

Click for Larger Image

Click for Larger Image

Marine Lithium Grease

Click for Larger Image

Click for Larger Image

Results

Granted, the force applied to each bushing was probably a few pounds per square inch different, but you can see in this general demonstration that the manufacturer’s silicone grease clings to the bushing much better than the lithium grease. Even though some of the manufacturer grease can be wiped away there is still a layer hanging on to the bushing and removing it completely is very difficult.

If this test didn’t satisify you then you’re going to love the next one.

The Major Adhesion Test (The Big Guns)

Now while your grease is not going to be directly hit with a powerwasher, pressure and water are some common obstacles that the grease coating on your bushings will go through. Since DST is still debating the necessity of constructing a state of the art laboratory, we improvised a stand, took each of the manufacturer’s lubricants, a Moly Lithium Marine grease, a Moly Polyurea Heavy Duty grease, and 80W motor oil and plastered it on 8 identical polyurethane bushings. We powerwashed the bushings at a distance of 12 inches then again at 6 inches for about 4 seconds. These are the results.

*DISCLAIMER: This test does not reflect the actual use of these products. We merely wanted to test the adhesion to polyurethane properties of the different lubricants in extreme conditions. Some of this grease is designed to adhere to metal better than polyurethane. No, this is not a sterile, precise laboratory test. Yes, DST’s patent-pending stand is made of wooden pallets and deck screws.

12 Inch Range, 4 Seconds

6 Inch Range, 4 Seconds

Prothane: Super Grease

Applied Grease

12 Inch Power Wash

6 Inch Power Wash

Energy Suspension: Formula 5

Applied Grease

12 Inch Power Wash

6 Inch Power Wash

SuperPro: WPGrease

Applied Grease

12 Inch Power Wash

6 Inch Power Wash

Daystar: Lubrathane

Applied Grease

12 Inch Power Wash

6 Inch Power Wash

WhiteLine: High Performance Bushing Lube

Applied Grease

12 Inch Power Wash

6 Inch Power Wash

Marine Grade Lithium Grease

Applied Grease

12 Inch Power Wash

6 Inch Power Wash

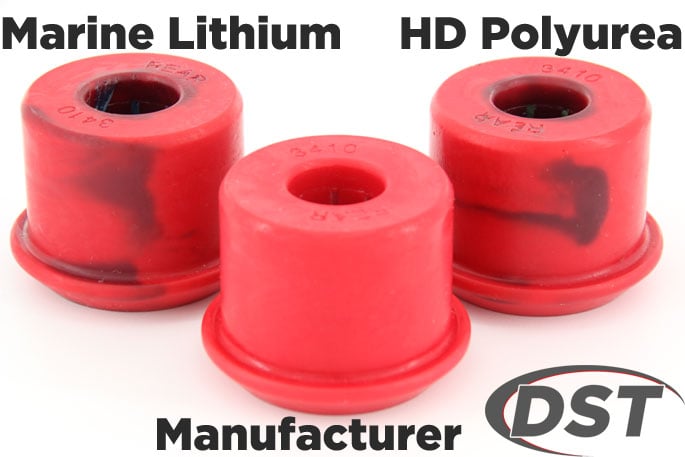

HD Polyurea Moly Grease

Applied Grease

12 Inch Power Wash

6 Inch Power Wash

80W Oil

Applied Oil

12 Inch Power Wash

6 Inch Power Wash

Results

It’s pretty clear from the pictures that the manufacturer’s silicone based grease held up the best.

All of the lubricants besides the HD Polyurea and 80W oil was still in place after the 12 inch powerwash. Prothane, Energy Suspension, and Daystar weathered the 6 inch powerwashing noticeably better than all the other lubricants. SuperPro started to give a little during the 6 inch wash, but performed better than Whiteline (the only lithium based manufacturer grease) which almost completely blew away. The Marine grease held steady with Whiteline while the HD and Oil were completely gone.

Consequences of Alternate Grease

After Effects of Greasing

We left the grease on the bushings overnight then cleaned them off with bleach wipes in preparation for their next test and noticed that some of the bushings didn’t come off clean. The bushings that were greased with manufacturer grease looked the same as before the test but the bushings that used the Marine lithium and HD polyurea grease were stained which could indicate some sort of chemical reaction.

After calling the manufacturer of these bushings they said that they strongly advise using the manufacturer supplied grease because some lithium based grease could actually cause the bushing to dry out and even crack.

If you were looking for a definitive reason to use the manufacturer’s grease it doesn’t get much more plain than that.

In Conclusion

There isn’t much that will degrade or otherwise harm polyurethane bushings, but enough friction on anything without the proper lubrication can damage it. While most lubricants will work for your polyurethane bushings the grease that the manufacturers supply is going to last the longest and allow the part to work correctly. If for some reason you don’t have access to the manufacturer grease then a silicone based lubricant with a PTFE additive is going to be the next best thing. Other than that there are many stop gap measures but for noiseless operation and the well being of the bushing you should apply the manufacturer’s grease upon installation and when you begin to hear squeaking or 5 years after install, whichever comes first.

So, what types of grease or lubricants have you used to successfully lubricate polyurethane bushings? Have you tried some type of lubricant that didn’t work very well? Please let us know in the comments section below.

From all of us at DST: Ride Smooth (and quiet), and Drive Hard.

Christian

January 26, 2018 at 9:22 amYou guys forgot to add SuperLube to your test. I would rate this grease for poly bushing as top 3 choice!

Josh Daniels • Post Author •

January 26, 2018 at 3:43 pmHey Christian,

We just tested the grease that we had on hand, but it looks like SuperLube has a silicone grease with a PTFE additive which fits the basic criteria of what we found to be good grease for polyurethane bushings. We can’t vouch for their grease personally but it’s probably better than used motor oil in a pinch. Most brands of poly bushings have their own grease that will come with the part (and we recommend using that) but a silicone PTFE grease is a good substitute.

Thanks for the input Christian.

David

November 18, 2018 at 7:49 amI’ve soured a little on Super Lube, which I’ve used for poly bushings on and off for years. I think it’s just too thin and not as tacky as the bushing specific option. It works ok if you happen to have grease fittings and can use it in a grease gun easily. But it just doesn’t have the staying power otherwise.

Josh Daniels • Post Author •

November 19, 2018 at 9:54 amYeah, the tackiness is a pretty important factor. Suspension travel puts bushings through a lot and you want that grease to stick around and keep the friction low.

Thanks for the insight David.

Barrie

March 6, 2018 at 8:08 amHas anybody tried KrazyGrease?

Josh Daniels • Post Author •

March 12, 2018 at 8:24 amHey Barrie,

It looks like krazygrease is petroleum based and meant for more of a metal-on-metal application like ball joints or tie rod ends. A silicone based grease is almost invariably going to stay on the bushing longer through more circumstances. Petroleum based grease might “work” for polyurethane bushings but the grease that the manufacturers supply is specifically made for poly bushings, so we suggest using that for longevity and proper operation of the bushing.

Thanks for the comment Barrie.

Mark

March 17, 2018 at 11:48 amMany years ago I installed Dick Guldstrand poly bushings in the front control arms of my 1970 Camaro. The upper bushings were a softer red and the lower bushings were a very hard dark grey color. At the time, they recommended using moly as a lubricant as it is a good extreme pressure lubricant. That did not work out well and they squeaked miserably. I finally removed the bushings and found that the moly had plated the bushings with a shiny dark silver coating. I agree that using the manufacturers lubricant such as the Energy Suspension lubricant is the way to go. I have a tub of that and it is very sticky. However, I wonder how they perform under extreme pressures?

Josh Daniels • Post Author •

March 19, 2018 at 2:18 pmHey Mark,

We totally agree with you about using the manufacturer’s bushing lubricant. I spoke with the folks at Energy Suspension about the extreme pressure factor and they had some insights.

First of all, the squeaking and other problems generally arise when the grease is simply gone. Some grease types are fine lubricants but do not have the staying power required to keep the bushings quiet and healthy. Energy Suspension’s Formula 5 silicone based grease with a PTFE additive will usually last for 5+ years and can lubricate with the best of ’em.

Second, the use of the vehicle and style of the driver is going to have a lot of influence over a poly bushing’s grease retention. If you’re clocking in A LOT of time at the track and driving the heck out of your car then you might experience some squeaking (which is a sign that the bushings need grease) before the 5-6 year mark when most poly bushings typically could use some re-greasing. Likewise for offroading, extended submersion in water, or high frequency of extreme suspension travel.

Lastly, the bushing style can have a significant impact on grease retention. Some manufacturers use grooves, knurling, cross-hatching, etc. to hold pockets of grease so that even when the bushing is really squeezed the grease won’t be pushed out.

Thanks for the question Mark, hope this was helpful.

Brian Mac

April 16, 2018 at 11:55 amJust FYI, Prothane & Energy Suspensions use the same grease!

Josh Daniels • Post Author •

April 17, 2018 at 2:13 pmHey Brian,

I would love to know where you got that information. Because of the proprietary nature of the formulas involved the manufacturers won’t say exactly what is in their grease. We have spoken with both Energy Suspension and Prothane about their grease and beyond saying that it is a silicone based grease with a PTFE additive, it’s proprietary. Here is some more details about Formula 5 Prelube if you’re so inclined.

All of that to say, yeah, they’re very similar. Whether or not they are exactly the same…

The point here is that you’re better off with the manufacturer’s grease (which most manufacturers include in their bushing kits) than with a different lubricating option.

Thanks for the input, Brian.

Tony

May 12, 2018 at 9:05 pmHey – Good work and thanks… I have been told, and found that, using some “grease” harms the bushings. Now, over my time at university, I spent a bit of effort creating moulds and pouring my own bushings to suit my own applications. After all that work no way would I put pure molybdenum disulfide (moly) “moly” on them. No freakin way, full stop. EVER. Surprised me that one of your test greases had “moly” added to the lithium formula to be honest. PTFE for the win here. Hell, even stick a pure nylon washer on the end if you are experiencing metal on metal problems. But that is truly getting off topic.

Like you say, chemical reactions can (and do) occur. The very fact you noticed them within 24 hours shows what could (and does) happen over months or years.

Also, just for reference, chemical nature of the resins means that when spraying a vehicle near the bushings you should be very careful to hide the bushings behind a plastic bag wrapped around the areas. The solvents in the acrylic paint can (and will) make a nice mess of the chemical structure of the bush.

Anyways, thanks for the write up. I hope it puts some people “right” on what to use. And may stop people thinking a certain bush manufacturer is producing garbage product and shooting their mouths off all over net stupid land about how their bushes fell apart.

Josh Daniels • Post Author •

May 15, 2018 at 10:17 amHey Tony,

We appreciate the compliment! It’s always cool to see a poly DIYer. Our intent with the write up was to try and show people that polyurethane bushings don’t have to be noisy and will last a long time if properly lubricated at install.

It’s hard to say for sure what the long term effects of different grease on polyurethane would be, but the color change in such a short amount of time seemed pretty significant. We don’t have the exact formula of the grease that contained the Moly additive, and we don’t have first-hand knowledge of how it performs (anyone?), but bottom line: silicone with PTFE is the standard for polyurethane grease.

Thanks for the tip about painting around poly bushings. They stand up really well against wear and the elements, but they aren’t impervious. Using the “right” lubricant goes a long way toward making them go a long way.

Have a good one Tony.

Tony

May 12, 2018 at 9:09 pmPS – Out of idle curiosity, in a sealed unit (eg – stuff the pressure wash test) has anyone looked into a graphite powder. In theory, could be okay. In reality, most likely complicated waste of time.

🙂

Josh Daniels • Post Author •

May 15, 2018 at 10:53 amWell Tony, when we say sealed unit in the post we’re referring to other suspension components like ball joints or tie-rod ends that have a sealed bearing where different types of grease can be used since they don’t have to worry about adhesion in the face of the elements like poly bushings do.

We talked with techs at Energy Suspension and Prothane about graphite powder on poly bushings and they gave similar answers: It might work, but you’re better off with the manufacturer supplied grease. The same thing has been said of Teflon tape, spray lube, and several other options. All that said, it might work great. Prothane’s black poly bushings do have a slight graphite impregnation so it doesn’t appear that it would harm the bushings, but whether or not it’s better than the grease… the manufacturers say go with the grease.

If anyone has first-hand experience with graphite powder on poly bushings please share!

Thanks for the curiosity Tony.

Rahul Sawarkar

June 19, 2018 at 1:30 pmQuick question – how much grease does one need per bush?

Josh Daniels • Post Author •

June 20, 2018 at 7:28 amHey Rahul,

The small 3oz tubes that come with most kits should be enough to handle several bushings. You just want to cover the surface that will be in contact with the sleeve with a thin layer and while you’re at it, give the sleeve a good coating too. You can put as much as you want, just be sure to wipe away any excess to prevent debris from getting caught in the grease.

Hope this helps!

Denis

July 27, 2018 at 6:09 amHello, first of all, it’s a very good post.

I would like to know if i use some silicone grease spray,if is good or not?

Thank to you,

Josh Daniels • Post Author •

July 27, 2018 at 8:29 amHey Denis,

It might depend on the spray, but as a general rule spray lubricant is not going to stick to your bushings very long. Especially if a lot of water or mud is being thrown around under your vehicle. If you’re coming up on your 5 year bushing maintenance mark and just trying to quiet your ride down until you have the time to tackle that job then a spray will last you a while, but it’s really just a band-aid.

Hope this helps.

Jason

August 5, 2018 at 9:45 pmI’m contemplating new Daystar polyurethane bushings for my 1987 Jeep leaf springs. They obviously recommend their own proprietary lube. I have settled on an NLG1 GC-LB (wheel bearing & chassis) lithium red grease as my go-to chassis lube as it was recommended by my drive shaft manufacturer and it works great for all the front end steering parts too. I would prefer to only have to keep one grease gun and one type of grease. If I shoot NLG1 red into my grease-zerk polyurethane spring bushings are they going to disintegrate with time or otherwise fail? I’m assuming that if I grease these bushings whenever I grease the rest of the chassis I don’t need to worry about running them dry. The previous rubber bushings have been run dry for close to 30 years and are in surprisingly good shape considering.

Thanks for all your work on this post. Great info.

Josh Daniels • Post Author •

August 6, 2018 at 2:51 pmHey Jason,

The short answer to your question is maybe.

We can’t say for certain that disintegration or failure would take place based on the type of grease you use. That said, In our talks with several poly bushing manufacturers, they’ve all touted their own grease as best, and all (but one) had one thing in common; they’re silicone based. This has a lot to do with the adhesion of the grease to the polyurethane surface, though some of the manufacturers have warned that lithium-based lubes might cause the bushings to dry out over time.

Another concern is that some of the additives in grease that is designed for machine application (chassis and bearing grease) could have, as yet unknown, effects on poly bushings. During our tests, we did witness color change in the bushings that were coated with multi-purpose grease that could be a symptom of a chemical reaction of some kind. Testing this would require some long-term observation and the sources we spoke with were not able to provide any hard facts regarding this.

I would imagine with frequent maintenance you would be ok using the grease you mentioned, but I can’t make any guarantees. With a Jeep I would probably ask, “what are you planning on doing with it?” If you’ve got a snorkel on your exhaust, and plan on using it regularly, you might reconsider going for another grease gun with a silicone based grease. If you’re staying above sea-level and not climbing rocks or burying the axles in mud you might be ok with a lithium chassis and bearing grease. Either way, your safest option for longevity is the manufacturer’s grease or a silicone based grease with a PTFE additive.

Does anybody have any long-term experience with lithium grease on poly bushings?

Hope this was helpful, Jason. And if you do go with the chassis grease please check back with us later and let us know how it’s working out.

Jason

August 10, 2018 at 10:08 pmJosh, thanks for the detailed reply. I replaced my leaf springs today and was happy to see that decades ago someone had installed Daystar polyurethane bushings for me, however, without grease zerks. These bushings have been totally dry for probably 20+ years and have not squeaked a bit. I had to shift them over to my new springs as I hadn’t planned ahead for new bushings, but these were in surprisingly good shape. I don’t have a website but if you want pics of 20+ year old unlubed poly bushings I have them. Since no one stocks silicone grease locally I had to put on a thin film of red lithium grease to re-install them, but I will get some silicone grease once I get some new shackles with zerks.

Josh Daniels • Post Author •

August 13, 2018 at 8:39 amThanks again Jason,

Daystar makes an awesome product so I’m not surprised to hear that your leaf spring bushings are still in good shape. I am a little surprised that they’ve been in there for two decades with no additional lube and haven’t made a peep! It stands as a testament to the excellent quality of the product since most manufacturers will tell you to regrease those bushings every 5 years. Shameless plug: We do sell the several manufacturers’ poly bushing grease including Daystar and Prothane which comes in a 14oz grease gun sized tube.

We would love to see those pictures! You can email them to datateam@suspension.com and we’ll add them to the bottom of your comment. Thanks again, Jason, and good luck with the new leaf springs.

Steve

September 12, 2018 at 5:06 amIs the silicone grease used on suspension the same as the dielectic silicone grease used on ignition components?

Josh Daniels • Post Author •

September 12, 2018 at 8:45 amHey Steve,

Both dieletic and some suspension grease use silicone oil but the thickeners and other additives could be different.

The term “silicone grease” can be kind of deceptive. Grease is oil mixed with thickening additives and a common base is silicone oil or petroleum. Since the exact formulas for these greases are proprietary it’s hard to say how they might be different. Dielectic grease is not supposed to contain elements that would promote arcing in electrical applications, but I can’t speak for poly bushing grease having the same property.

In any case, it’s probably best to use the individual greases for their intended purposes. In a pinch, if you have dielectic grease that’s silicone based with a PTFE additive then you would probably be ok putting it on polyurethane bushings, but there could be unintended effects because of other additives. I wouldn’t try using a poly bushing grease for electrical purposes though.

Hope this helps, Steve.

RandyO

September 30, 2018 at 7:03 pmWell appears that it is more about composition than brand.. I would guess almost any full synthetic with PTFE is going to rate just fine..

I am also drilling and fitting grease zirks.. Just seems a nice little flush every now and then might save a bunch of work later…

Krissy Rose

October 2, 2018 at 7:02 amHey RandyO,

Yes, you’re right. Grease with a silicone base and a PTFE additive should do the trick. The only potential problems could be the effects of other additives in grease not designed for poly bushings. As for Zerk fittings, we’re also partial to them. It is good to refresh your old grease from time to time to keep everything working properly, especially if you are in mud, slush, or water on a regular basis.

Bill

March 9, 2019 at 10:04 pmGreat information, I do have some additional questions (hopefully someone is monitoring this). i have a 92 leaf sprung jeep (OME springs) I am pulling out all the bushing and regreasing them. i also have greaseable bolts on all the springs and at the frame. In the past I have been using Amsoil Synthetic water resistant Lithium compound grease. I have had issues with the holes in the greaseable bolts clogging, Then I can’t lubricate the bolts/sleeves. I assume this is due to the grease getting dried out. Only way to resolve is to pull everything apart, clean grease and reassemble. So if I use the silicone based lubricant this time on the outside of the bushings do you recommend using the same lubricant on the bolts and sleeves?

Another questions, when I lubricate the greaseable bolts should I expect the lubricant to actually squeeze between the bushing halves and work it’s way to the outside of the bushing?

Josh Daniels • Post Author •

March 12, 2019 at 12:17 pmHey Bill,

In talking with different poly bushing manufacturers we got the consensus that lithium grease isn’t recommended. Some manufacturers go so far as to say that lithium grease can dry out poly bushings, possibly shortening their effective lifespan. Some brands can also get a little sticky about their warranty if the recommended grease isn’t used.

All of that said, you can use any grease you like, but the manufacturer’s grease or a silicone based substitute with a PTFE additive is going to be your best bet for proper operation and longevity.

Mixing lubricants is generally not a good idea since different types are rarely compatible. Best practice would be to use the same grease for the inside and outside of those bushing positions and using the manufacturer recommended grease is advisable.

I don’t know what brand of bushing you have but I just got off the phone with a tech at Daystar who specialize in offroad aftermarket suspension bushings. He informed me that their greaseable leaf spring bushings are notched in a way that allows grease to flow from the inner surface to the outer surface of their bushings, so liberal greasing should cover both surfaces. If your bushings were designed to work with greasable bolts they likely have a similar feature, but if not you could probably DIY a solution.

Thanks for the question Bill and hope this helps.

John Fernandez

March 10, 2019 at 11:05 amAny feedback on Mobil 1 Synthetic grease?? I know a Miata guy that swears by this stuff for Sway bar Poly bushings??

Josh Daniels • Post Author •

March 12, 2019 at 12:30 pmHey John,

Anytime we bring up grease for poly bushings with the manufacturers the answer is always “Use the provided grease. It’s designed to work for poly bushings.”

Outside of that, the best alternatives we’ve found are silicone based grease with PTFE additives. That’s not to say that other alternatives won’t work, they just might have other long term effects on the bushing or might wear away and cause squeaking. The grease you mentioned also uses Lithium additives which some bushing manufacturers have said could dry out poly bushings and affect their lifespan.

Do you know how often your friend regreases his sway bar bushings? The grease is listed as having “slight tack” which means it might not stick very well with hard driving or wet conditions. The manufacturer grease should last longer.

If anybody else has real-world experience please let us know. Hope this was helpful.

Bill

March 12, 2019 at 2:52 pmHey Josh

That does help a lot and I appreciate your time. I have some daystar bushing and they are grooved internally (the part that is in contact with the metal sleeve). I also have some Old Man Emu bushing and they are the opposite, i.e. grooves on the outside of the bushing i.e. the surface that is in contact with the spring. Like most manufacturers the bushings are two pieces, I can only assume that the manufactures think, believe or have tested such that the grease could migrate between the halves to the outer surface. I have not found that to be the case. Regarding Lithium grease I have been using amsoil (just because I thought it was betterthan cheaper products) and though I have not seen bushings deteriorate I have the issue mentioned, i.e. grease gets thick and clogs the grease holes. My bushings got dry and really started to make horrid noises. Thus part of the reason I am tearing all my bushings out and re-greasing them. I will try on of the products mentioned above for internal and external bushing lubrication.

Oddly enough a jeeper friend of mine said a manufacturer told him to only use white lithium.

thanks again for this resource

Bill

Josh Daniels • Post Author •

March 15, 2019 at 7:07 amNo problem Bill,

Glad you found the information useful! Please feel free to let us know how the new grease works out for you or send some pictures of those bushings. I imagine the problems you’ve had will be solved and you shouldn’t need to take on a project like this again anytime soon.

As for as the grease penetrating that space between the bushing halves, the Daystar tech seemed pretty sure that it shouldn’t be a problem. Of course, you’re the one actually pumping grease into the bushings 🙂

It’s interesting that your friend got that information from a manufacturer since techs from several bushing brands have told us that they would always advise using their own grease (silicone/PTFE) over any lithium grease. I’ll be sure to bring it up again next time I talk with Daystar.

Hope it all goes well.

Erik Aguero

April 15, 2019 at 3:23 pmFirst thanks for all the info! Do you know where I can find Formula 5 Polyurethane Bushing Grease tubes for my grease gun or do they even make any. The reason I ask is because my truck has zerk fitting to lube the bushings and someone before me greased all the bushing with the wrong grease and exactly what you said above is happening to my bushing they are staring to dry and crack so I’m replacing all 8 in the rear. But I’m greasing them with little Formula 5 Prelube – 5 mL tubes as I replace them but if I ever want to grease them on the truck I would need to do it with my grease gun thru the zerk fitting or I would have to take them apart to grease them again.

Josh Daniels • Post Author •

April 18, 2019 at 1:40 pmHey Erik,

Energy Suspension doesn’t carry their grease in cartridges but you can buy Formula 5 in quantity (up to a gallon) and fill a bulk grease gun with Formula 5. If you’re trekking through mud or other harsh elements this will give you an easy way to maintain the bushings when they need it. There are some other manufacturers that have comparable grease that comes in cartridges, but if you want Formula 5 in a standard grease gun you’ll likely need to load it yourself.

Are the bushings that you had before poly or rubber? If you wouldn’t mind sending some pictures of the cracked bushings we would love to see them. It would help drive home the importance of bushing maintenance.

Thanks for the question Erik.

Ben

June 26, 2019 at 12:38 pmDo the same rules apply for rubber bushings? I came across this thread searching for the best grease for my Polaris ATV suspension arm bushings. Unfortunately I do not know what the factory bushings are actually made of.

Ben

Krissy Rose

June 28, 2019 at 1:54 pmGood Question Ben!

Actually, the rules for greasing are different for rubber. In fact, rubber bushings do not need to be greased at all! The reason for this is in a rubber bushing set up there are no moving parts; the rubber is vulcanized into the metal. Now if these bushings become worn or damaged they will begin making noises or causing other issues in your Polaris.

If this occurs the bushings either need to be replaced with OEM bushings (rubber) or with Polyurethane bushings. The rubber bushings you will eventually start having the same problems and they will need to be replaced again. Polyurethane, on the other hand, will never need to be replaced but will need to be greased every so often.

If you’re wanting more info or more explanation on the two bushings we have a Blog Post specifically about ATV bushings. I hope this helps!

kris limmer

April 2, 2020 at 10:03 pmmy super pro bushings were 100% dry after 3 months on a road and show car,

it was almost impossible to remove the center steel bush to relube, i’m thinking of trying copper grease

next time.

Josh Daniels • Post Author •

April 8, 2020 at 9:48 amHey Kris,

I have to ask, were the bushings greased during install?

I spoke with a representative at SuperPro and his best guess is that maybe the bushings came pre-assembled when they were shipped. Sometimes bushing kits will be assembled before shipping to make sure that all the correct parts are included or to reduce package size and save shipping costs. If the bushings and sleeve was already assembled in the packaging it’s almost certain that they were not pre-greased.

From the details provided this seems to be the most plausible scenario. The grease that SuperPro supplies with their bushings is incredibly tacky and 3 months of road and show car use should not be early enough stress to displace all of the grease. Possibly an inadequate amount of grease was used but after only 3 months I would expect some residual grease at least.

If you greased them yourself with the supplied lubricant then I am obviously wrong and fascinated and would really like to know the make/model, bushing position, and any other details so we can try and figure out what happened.

As for copper grease, the debate over which grease is best for poly bushings will likely never be completely settled. We’ve talked with techs at several poly bushing manufacturers and they all say “use the supplied grease” and that grease is almost always a silicone base with PTFE among other additives. Most of the copper grease I’ve seen has been marketed as “anti-seize” which isn’t to say that it wouldn’t work as a lubricant for poly bushings but those are slightly different categories.

All that to say, there are people who will swear by copper grease and use it without a problem, but the other niggling detail is that warranty claims on a poly bushing could be denied if the supplied lubricant isn’t used. Since most of the manufacturers use a similar grease (and they have an vested interest in providing customers with something that works) it’s best practice to use the manufacturer grease.

Thanks for sharing your experience Kris and good luck.

rick

April 11, 2020 at 10:46 pmI read somewhere to use teflon tape. I wrapped it around my sway bar before putting the new sway bar bushings over the top. I looked it up and it’s PTFE aka Teflon.

Sorry, but I haven’t crawled back under the car since. It was about 2 years ago.

Josh Daniels • Post Author •

April 13, 2020 at 9:15 amHey Rick,

Wrapping the bar where the bushings sit with Teflon tape has been touted on many forums and by professional mechanics as a good measure to take when using polyurethane sway bar bushings. A point of note, this is usually advised in addition to using grease, not in place of, and since almost all poly bushing manufacturers supply grease with their bushing kits there’s no reason not to use the grease.

Also you may want to check with the manufacturer and make sure that using the tape will not void the warranty on the bushings, as they can get sticky about folks not following the installation instructions and then claiming the product is not working properly. SuperPro actually warranties their bushings against squeaking IF the instructions are followed which includes using the supplied grease.

We would probably not advise using the tape because of the possible warranty issue and since properly applied grease from the manufacturer will get the job done solo. That said there are plenty of cases where it has worked really well for some folks so it has some merit as an extra line of defense against squeaking poly bushings.

If you do get a chance to check out how that tape is looking let us know how it’s holding up after 2 years. Thanks for the suggestion Rick. Stay safe out there.

Mark Simcoe

June 4, 2020 at 11:15 amI use a polyurethane grease from Mission Automotive which is silicone grease (dielectric grease). I then mix in a reasonable amount of graphite powder. A forum member on one of the 4Runner forums suggested this and I have recently been using this mixture. It turns the clear grease black when you mix the graphite in. I really have not been using it long enough to have an opinion one way or the other but, in the short amount of time the bushings have been installed (3-4 months) I have not heard any squeaking and on the occasion when I had to replace one of the control arms I moved the poly bushing to the new arm and there was still plenty of grease in and around the bushing after about 2 months.

Josh Daniels • Post Author •

June 8, 2020 at 9:14 amHey Mark,

Powdered graphite is an excellent lubricant and is even marketed as a lubricating additive for oils and grease. Graphite infused polyurethane bushings were actually pretty popular at one point as a method to reduce the chance of squeaking, but the effects were minimal without also using grease so now almost all poly bushing companies provide their own approved grease with their products.

The unofficial industry standard for poly bushing grease is that you should not notice squeaking for about 5 years (or ever as some brands like SuperPro claim) if the proper grease is used during installation. Bushing material and design is also a factor when it comes to squeaking or if you are burying your axles in mud on a regular basis then your ‘results may vary’, but generally speaking you should get at least 5 years of quiet operation from your bushings with the right grease.

I’m not sure how homemade poly bushing grease stacks up against the manufacturer grease but I would love to hear about your long-term observations as you put more miles on those bushings.

Thanks for sharing the greasing option Mark and good luck.

Andrew Durkee

July 8, 2020 at 6:15 pmWondering how Molykote 111 holds up compared to these greases.

Josh Daniels • Post Author •

July 15, 2020 at 11:52 amHey Andrew,

We don’t have any first-hand experience with that lubricant but it appears to have some of the earmarks of good poly bushing grease, such as a silicone oil base, but there are some issues.

All but one of the manufacturer’s lubricants we looked at used PTFE with silicone grease along with some other additives, so not sure about silica being used as the thickener or what effect it would have on bushings. The lubricant you mentioned is marketed for rubber and plastic applications in harsh environmental conditions so it might serve as a substitute, but as always we recommend going with the manufacturer approved grease.

Does anyone use this lubricant with poly bushings and want to weigh in?

Thanks for the tip Andrew.

Matt

February 16, 2021 at 8:01 pmThis article popped up in my google feed just now as I’ve ordered a bunch of suspension components for my new to me lifted v8 4Runner 4×4. I have a grease gun loaded with synthetic grease I use on my SRT Neon but seeing as the cartridge is already inside the gun I do or know if it’s a silicone based grease with PTFE additives or not. I may have to splurge on another grease gun for my truck! Thanks for the deep drive into polyurethane bushing lubrication. Thirty years ago when my dad was actively building numerous hot rods for himself and a lot of customers and friends the use of poly bushings was just coming into its own. Yes they were notoriously squeaky! So much so that many people removed them in favour of the old rubber bushings that were essentially silent. Even greased they’d make noise within a year of fair weather street driving. I know guys that still have those same bushings installed in their hot rods to this day and they complain of the squeaking still. I shall be mentioning what grease they should be using next time the subject comes up! Again, thanks for this.

Matt

Josh Daniels • Post Author •

February 17, 2021 at 10:33 amHey Matt,

Thanks for the kind words! We’re glad you found the info useful!

Poly bushings have had a bad rap in the past for the squeaking and while the older formulas and designs were sometimes to blame a lack of grease was/is almost always the culprit. To get the best results from polyurethane bushings they need to have proper lubrication, and honestly it’s good for us and our customers that they get the best performance from their bushings.

Thanks again, Matt, and spread the word!

Evan

March 2, 2021 at 7:56 pmOnce you have the silicone based grease all over you, your tools, your car/truck, the dog, etcetera, what do you recommend using to wash it off?

Josh Daniels • Post Author •

March 5, 2021 at 10:30 amHey Evan,

Yeah, that stuff can be annoying, but you can use Dawn dish soap for all your cleaning needs. For the hands you could use your run of the mill post auto work cleaner like GOJO or Fast Orange.

Good luck in your cleaning endeavors!

Thom

May 20, 2021 at 6:04 pmI have been using CRC Brake Caliper Synthetic Grease for over 20 years. Prior to that, I was trying other products like Super Lube with PTFE, Slick 50 One 1 Grease with PTFE, etc. But the CRC lasts for years before the squeaking returns. Last time I applied it was in 2017. The stuff is thick and sticky. I learned of this from the guys at Jackson Racing back in the early 1990’s. They used Motul Synthetic Brake Caliper Grease, but told me it’s hard to get in the US. So they suggested the CRC which they also use. Has any one else used CRC?

Josh Daniels • Post Author •

May 25, 2021 at 2:36 pmHey Thom,

The lubricating components in those suggestions look good and if the tackiness is up to snuff then they wouldn’t be a bad option. The base of the CRC grease appears to be a petroleum derivative so that might be the only issue with applying it to polyurethane bushings, but we haven’t tested that particular grease.

Kris Fraser

August 25, 2021 at 4:50 pmyou shoudl only use silicon grease on urethane. Petroleum based grease will break down the urethane and cause premature bushing failure.

Josh Daniels • Post Author •

August 31, 2021 at 8:32 amHey Kris,

Whenever we’ve talked with poly bushing manufacturers about grease they’ve told us much the same thing – Petroleum grease could cause polyurethane to dry out and degrade the bushing.

David Shaffer

February 22, 2022 at 8:21 amHas anyone tried mixing in graphite with the silicone lubricant?

Josh Daniels • Post Author •

February 25, 2022 at 12:19 pmHey David,

While we love experimenting we would caution against mixing in additives with grease, unless you are a chemist 🙂 Early grease was basically oil and soap but these days there are complicated and proprietary formulas involved with lubricating agents and adding other substances could have some unintended consequences.

The PTFE (teflon) that is used in most preferred poly bushing grease is possibly the most slippery substance devised by man and does the job of reducing friction in bushing operation really well. Since graphite is also a lubricating material there could be benefits to mixing them but it would be a good idea to contact the manufacturer of whatever grease you are planning on mixing to make sure there are no known issues.

Hope this was helpful.

Chris

April 1, 2022 at 4:06 pmSome thought- Silicone is soluble in gasoline. Since all roads have an amount of gasoline and other chemicals on them from drips here and there could it be that during rainy days the water and gas + other chemicals are acting as a pressure/ flush and helping to dissolve the silicone leading to squeaks?

If this is the case wouldn’t it be better to use a grease such as Krytox GLP205? It uses a PFPE base oil and thickened with PTFE powder. PFPE is highly resistant to gas and oil and may not be as effected by the chemical onslaught. It IS more expensive and manufacturers are definitely not above cutting costs.

Josh Daniels • Post Author •

April 12, 2022 at 7:15 amHey Chris,

The grease looks good but we would say there are at least two reasons we can think of why Krytox GLP205 would be a little overkill as a poly bushing grease.

1) Like you said, it is more expensive. About double the price of manufacturer supplied grease.

2) We do not have any evidence of the poly bushing manufacturer lubricants being dissolved away.

Of the thousands (maybe tens of thousands by now) of customers who have installed poly bushings with the manufacturer grease we have received less than a handful of complaints of squeaking even after a period of years. It’s pretty unlikely that someone wouldn’t have given us a call in that time if the supplied grease was not preventing squeaks.

The GLP205 would likely work just fine, but given that there is a much cheaper option out there that gets the job done, and comes free with the bushings in a lot of cases, there is no real benefit to spending the extra money.

mike petty

June 16, 2022 at 6:31 pmThe problem is with GM upper & lower A frame bushings there is no grease fitting to lube the upper & lower A frame bushings after installed. When I installed the polygraphist A frame bushings I used the correct supplied grease, but after 15,000 miles the bushing have started to squeak and now, with no way to force grease in, now what?

Josh Daniels • Post Author •

June 23, 2022 at 7:40 amHey Mike,

Yeah, most control arms do not have a grease fitting for the bushing positions. Most poly bushing manufacturers advise re-greasing the bushings after 5 years, which requires taking them out of the control arm in most cases, but they should not be squeaking after just 15k miles.

Some very mechanically inclined folks who spend a lot of time at the track or off-road have taken such steps as installing their own grease fittings in control arms to allow for frequent grease maintenance, but those are generally cases of extreme use of the bushings.

Knowing your model, what kind of driving you are doing, what your local climate is like, and what brand of bushings you bought could possibly provide some clue as to what happened, but according to our customer feedback this appears to be an outlier. We have heard from many poly bushing users whose bushings are still functioning quietly after 5+ years of operation so it is strange that yours are making noise after such a short span.

Todd

June 19, 2023 at 10:11 amCan you use permatex 80078 for lubricant? Saw it mentioned online somewhere and was curious if this was tried? Also, teflon tape on the bushing before lubrication?

Josh Daniels • Post Author •

June 21, 2023 at 12:53 pmHey Todd,

The Permatex 80078 lubricant appears to be intended for metal-on-metal lubrication. That’s not to say that it would not work for poly-to-metal applications, but it doesn’t seem to have been designed for that purpose.

It does have a petroleum base which some poly bushing manufacturers have said is not a great option since petroleum can have a degrading effect on polyurethane over time. There have been folks who have used graphite powder and said that it works well, but that was not included in our test so we can’t say definitively one way or the other.

While Teflon (PTFE) is a main ingredient in most polyurethane bushing lubricant a solid tape instead of a silicone based grease would not be the best method. Since poly bushings are a free float design the tape would get pinched between the bushing and the housing (of a control arm say) as the arm articulates and I imagine the tape would be torn up in short order.

Again, no real world experience with this one, so if someone has tried Teflon tape on poly bushings it would be interesting to know how it went…

Thanks for the question Todd!

Dever Sanderson

August 3, 2023 at 11:14 amIn conclusion, I want to express my gratitude for sharing your expertise on this topic. Your blog post serves as a valuable resource for anyone seeking to maintain and optimize their vehicle’s performance by using the best grease for polyurethane bushings. Keep up the fantastic work!

Josh Daniels • Post Author •

August 7, 2023 at 7:38 amHey Dever,

Thanks for the kind words! We just try to pass along any helpful knowledge to folks who are trying to sort out their own steering and suspension.

Have a good one!

Tri

November 5, 2023 at 6:15 amGreat article and overview of manufacturer’s grease type – silicone.

Someone here mentioned using brake caliper grease on bushings which is ok. What about the reverse? Bushing grease on brake sliding pins etc. I assumed it was ok since it is silicone based. I’ve been using that because I get leftover bushing grease packets. So far it’s been ok…

Josh Daniels • Post Author •

November 7, 2023 at 11:56 amHey Tri,

You should always try and use grease that has R&D behind it for that specific application, but many lubricants for brake parts are silicone based like poly bushing grease. It looks as though the big difference would be that brake grease generally uses a ceramic solids additive while bushing grease typically uses PTFE. For metal-to-metal applications you may want to do a little more research, but poly bushing grease is a good option when the grease may come into contact with rubber or plastic components.

Thanks for the comment and Captain Planet thanks you for reusing your bushing grease packets 🙂

Chris Snyder

December 28, 2023 at 10:59 amGREAT WRITE UP! I love the “almost obsessive” testing.. including power washing at 6″ and 12″.

I just got polyurethane stabilizer and sway bar bushings as I replace front suspension parts on my 1993 GMC 1500 w/208K miles. Within the original sleeve and bushings, the 5/16″ sway bar link bolts had rusted to thickness of a round toothpick, so I want something that’ll repel water and lube contact surfaces. I was going to use my “go to” silicone lube of GM dilectric grease, but don’t see PTFE in the “contains” list so ordered Energy Suspension Formula 5.

Interesting about Marine Lithium grease causing discoloration. I put this on tie rod sleeves to stop/discourage Missouri winter salt rust, but won’t use it on poly bushings.

Again, thanks for the information. I googled “can i put silicone grease on polyurethane stabilizer and sway bar bushings”, got this for the first hit, and have been on inet for over an hour reading about this… is nice to have time. Always good to learn the right way to do something after 50 years of working on cars.

Josh Daniels • Post Author •

December 29, 2023 at 9:00 amHey Chris, thanks for the kind words!

We had a good time putting that little experiment together. Even though your bushings aren’t getting power-washed everyday it gives you a good idea of how much the different greases can handle. In all honesty the GM grease might be fine since it’s a silicone based lubricant. The rub is the silica thickener or the other additives which we couldn’t vouch for. You never know what the extras might do so better safe than sorry by going with the Formula 5.

Happy to know that you found it a good information resource for lubricating your polyurethane bushings and we applaud the “always learning” attitude. With 50 years of turning wrenches on cars under your belt we’re sure there’s a thing or two you could teach us 🙂 and good job/good luck keeping that 1500 going!

Have a good one Chris.

Taher Ryad

January 30, 2024 at 11:36 amExcellent test, question here any alternative to the supplied grease with lighter viscosity for periodical maintenance?I have energy suspension sway bar bushings kit with zerk fitting and I will bulk load mini grease gun.

Josh Daniels • Post Author •

January 31, 2024 at 10:26 amHey Taher,

Higher viscosity is usually desired so the grease stays with the bushing better. What is your reasoning behind a lower viscosity?

How often you perform lubrication maintenance for those bushings will depend on a few factors like vehicle use and road and weather conditions.

In many cases a well greased poly bushing from Energy Suspension should go 5 years without requiring more grease. But if you’re talking about a truck or SUV that gets a lot of mud thrown around underneath, or you live in an area where the roads are wet, muddy, or salted for ice, then you may want to apply grease more regularly.

If you just want to be preemptive with your maintenance finding a silicone grease with PTFE will be a good bet.

Hope this was helpful.