What are Sway Bar Links and Bushings?

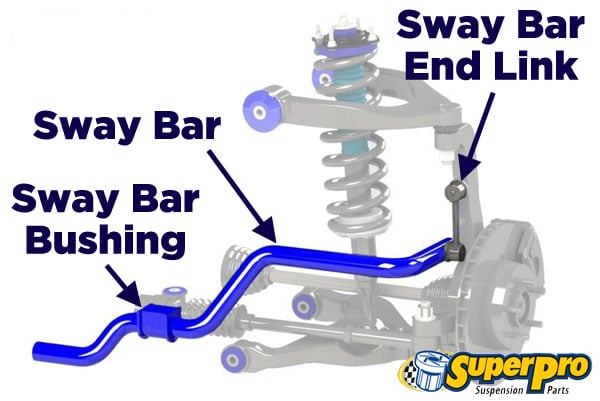

The sway bar (stabilizer bar) is a long metal rod that essentially connects the driver and passenger side suspension and keeps both sides more level during a turn.

- Sway bar links (end links) connect the ends of the sway bar to the driver and passenger side suspension.

- Sway bar bushings are the fulcrum of the sway bar and attach it to the frame of the vehicle.

Driving with damaged or even missing sway bar bushings or links can be dangerous since the sway bar mitigates a lot of body roll, meaning your vehicle tilts less to the outside during a turn. So making sure the sway bar is securely connected is important for safety and vehicle performance when turning.

Symptoms of Bad Sway Bar Links and Bushings

The most obvious signs of bad sway bar links and bad sway bar bushings are –

- Noise (clunking, knocking, rattling)

- Metallic Sound going over bumps

- Excessive Body Roll

- Sluggish Turning

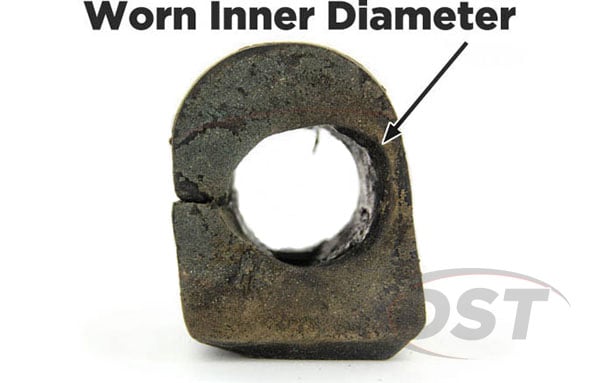

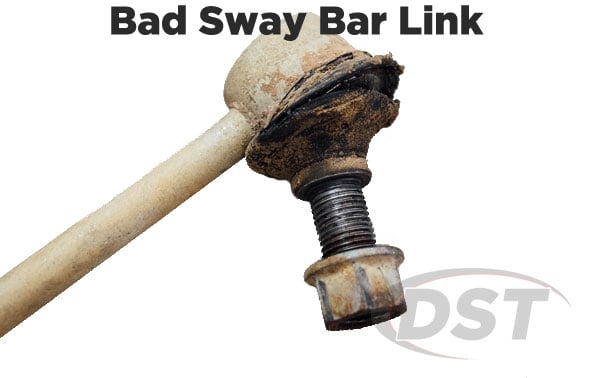

Sway bars act as a lever during a turn and transfer suspension travel from the outside to the inside wheel which keeps the vehicle more level, reducing body roll and maintaining traction for better handling. Since the bar twists to achieve this, the OE rubber bushings that hold the bar to the frame can become hollowed out or misshapen from the constant torqueing and the end links that connect the bar to the lower control arm or strut can also wear out at a fast pace.

Checking Sway Bar Links / Bushings

If these symptoms are happening then manually checking the sway bar links and bushings for damage is a good idea. This will confirm that the links or bushings are in fact the problem and the noise isn’t coming from some other part that might need attention.

- Jack up the vehicle and secure it with jack stands or blocks

*Place the stands in such a way that the suspension is supporting the weight of the vehicle - Locate the sway bar

- Move the sway bar up and down

- Observe the end links and bushings

If you can see looseness in the end links when you move the bar then they should be replaced. If the bushings are showing signs of deterioration (cracking or brittleness) or they have a gap or are misshapen then they also need to be replaced.

Sway Bar Link / Bushings Replacement Cost

The actual cost of replacement sway bar links ranges from $20-$100 (replacement – premium) and sway bar bushings from $10-$30 with most of the total replacement cost being labor, which averages around $70-$100 per hour.

There is good news in that if someone is moderately, mechanically inclined replacing sway bar bushings and end links is a simple job that can be done in the home garage and the only cost is that of the parts and a little time.

Some brands of sway bar links are sold as a low cost replacement while others are designed for higher performance and the price will reflect this. For vehicles with custom suspension, or older, rarer models, you may need to take measurements and find a universal sway bar link that fits your requirements.

Another aspect of replacement cost for sway bar links and bushings can be frequency. If you own a vehicle for a while and commute long distances, drive on rough roads, or take your vehicle off-road then the end links and bushings will likely need replacing. You can use OE replacements which will have a similar lifespan to the originals or you could use polyurethane bushings which have exponentially higher longevity.

Benefits of Poly Sway Bar Links and Bushings

For straight style sway bar links, polyurethane grommets make the connection more solid and increase the sway bar’s ability to reduce body roll. Polyurethane sway bar bushings grip the sway bar better than the original rubber bushings and are much more durable.

Poly sway bar components provide no downside other than when they are installed without being greased properly they can squeak. One of the easiest and cost effective ways to reduce body roll is exchanging worn or damaged rubber sway bar bushings with polyurethane. When the sway bar is secured more tightly to the frame and connected more securely at the ends the bar actually functions like a larger diameter bar, giving higher performance in handling.

Conclusion

Replacing sway bar bushings and end links is an easy DIY job that can make a big difference in how your vehicle handles corners. If you are looking for an even more dramatic improvement in body roll reduction then polyurethane sway bar bushings are a very simple upgrade over the original rubber bushings. Here are some brands we recommend (and sell) if you need to replace your sway bar bushings.

Brit

December 2, 2021 at 7:28 amI have a lift on my truck right now. Could that be causing my end links to fail prematurely?

Josh Daniels • Post Author •

December 2, 2021 at 4:56 pmHey Brit,

It depends on the lift and your style of driving but if both are nominal then probably not.

The size of the lift makes a difference but body lifts make minimal center of gravity changes while a suspension lift can raise as much as 90% of the vehicle’s weight. Raising the center of gravity of a vehicle can increase body roll which the sway bar is acting to reduce so this could put more stress on the links and bushings, but if you are not aggressively taking corners then you should not experience much more than normal wear and tear.

Hope this was helpful.

Brit

December 17, 2021 at 7:04 amThank you, Josh! No aggressive corning in this truck, just some trail exploring and overlanding. Currently only have a 2.5″ lift and I am pretty happy with that right now. Thanks again for the information.

GREGG

May 27, 2022 at 1:14 pmWill I need to get an alignment after I replace my sway bar bushings? Or after I replace the end links?

(I know I need an alignment after I replace struts or control arms, but haven’t found a good source of info for related parts like the above or like tie rod ends, ball joints, etc.)

Josh Daniels • Post Author •

June 1, 2022 at 7:26 amHey Greg,

No, you do not need an alignment if you are replacing the sway bar, bushings, or end links.

The sway bar is just connecting the driver and passenger side control arms and does not affect the alignment of the wheels. You will want an alignment when replacing or adjusting the control arms, ball joints, tie rods, or component that affects the position of the wheel.

Hope this was helpful.

Tyler

August 13, 2022 at 5:22 amThe bushings in my end links are toast and I am trying to change out the bushings the links themselves are good I just need the bushings replaced I have a 94 explorer XLT how you you get the old bushings out so I can put the new ones in anyone got any ideas

Josh Daniels • Post Author •

August 16, 2022 at 7:58 amHey Tyler,

Since the rubber bushings are molded directly into the end link your best method for getting them out is to heat up the housing around the bushing and melt the rubber. Then you should be able to just push them out. Here is a How-To for removing bushings that goes into more detail.

As far as putting the new ones in, it can be a bit of a hassle with OE style rubber bushings requiring a press. Polyurethane bushings are very simple. They come in two halves that you just stick in each side and bolt on. Poly sway bar end links also last much longer and keep the sway bar more secure than rubber bushings.

If you still need some we have replacement end link bushing kits for the ’94 Ford Explorer. Hope this was helpful and if you run into any other questions feel free to ask. Good luck with the removal and install.

Emil

August 21, 2022 at 6:57 pmHi, my control arm bushings need to be replaced and the mechanic is telling me they also need to replace the sway bar links at the same time because they are connected. My sway bar links are in good shape though. Just want to make sure that is true. Can they not put the old ones back on if they are still good? It’s for a 2011 forester.

Thanks!

Josh Daniels • Post Author •

August 22, 2022 at 8:13 amHey Emil,

Without inspecting the links ourselves we can not say for sure whether or not they need replacing, but just having the control arm bushings replaced does not make replacing the end links a necessity.

If the mechanic is acting in good faith then he probably means that since you are already having work done on the control arms, replacing the end links could be done at the same time and save some labor cost if you need them done in the near future. If your Forester has a lot of miles and you are planning on keeping it for a long while then you might consider getting the end links replaced, but again, if they are in good shape it’s not a necessity.

Hope this was helpful and good luck with the new bushings.

Andrew Bibay

September 8, 2022 at 8:34 pmI checked my Lexus IS250 sway bar links just for the hell of it. So, I see that I can still move it, but it takes a little bit of an effort. I know if the sway bar is very loose and easy to move around, then it’s gone bad. I’m curious, if it takes kind of an effort to move it a little, how much life does it have? It’s something to keep an eye out for in the future? No weird sounds or steering issues. Nothing that screams “Broken”.

Josh Daniels • Post Author •

September 9, 2022 at 8:35 amHey Andrew,

It doesn’t sound like you have anything to worry about. The sway bar will have a little movement, especially if you really crank it, but you should not get much.

How much life your sway bar bushings and end links have left in them depends on a few factors like mileage, driving style, road conditions, and even climate (road salts on icy roads or salty sea air can accelerate rubber bushing deterioration).

If its not very clear that the bar is loose then you can visually inspect the bushings for gaps or deterioration. You can try using a smart phone to video how the bushings react to you moving the bar if there isn’t a good angle for observation. If there are clear gaps or signs of wear and tear then replacing those bushings will almost certainly provide a noticeable difference in handling, more so if you go with poly bushings opposed to rubber.

The ball joint style end links on that model Lexus can be checked by unbolting the end link from the control arm and checking the state of the ball stud. It should provide a little resistance at least, so if the stud rocks back and forth with a little tap or rolls around freely then you should get some new end links.

Hope this was helpful and thanks for the question.

B. Washington

November 12, 2022 at 10:07 amHi,

My passenger side shakes once my 2011 Lexus ES350 reaches 60+ mph. Does needing a replacement sway bar system cause this effect?

Josh Daniels • Post Author •

November 14, 2022 at 10:56 amHey B,

No, the sway bar is not going to cause a shake in the front end. The sway bar reduces body roll during a turn but doesn’t directly affect the wheels and will not produce a shimmy or shake when driving at speed.

Could be an issue with the tire, control arm, strut, wheel hub or bearing… basically anything that has some hand in keeping the wheels aligned. Our resident mechanic, Ed, said that a slipped belt or bubble in the tire is the most common culprit or an off-balance tire. Barring that, other wheel alignment components are the next suspects along with problems in the drive line.

Hope this was helpful and good luck getting that shake squared away.

Zachary Seales

February 3, 2023 at 8:30 pmI have a 2007 Toyota Corolla LE with the 1.8l engine. Just trying to figure out what the “clunk” sound is when hitting bumps or dips in the road regardless of speed. Everybody keeps telling me that it’s just a common corolla issue without actually helping me to diagnose the issue at all. If you know anything that I do not, please inform me so I can stop just throwing money and parts at this to get the issue fixed sooner than later.

Josh Daniels • Post Author •

February 6, 2023 at 3:25 pmHey Zachary,

The infamous “clunk” noise can be attributed to a lot of issues so it can be hard to pin down.

Putting the car up on blocks (very securely) and just trying to shake or move suspension components until you find something loose may be your best bet. Any connection point could be the culprit but then again it might not. A trusted mechanic looking at the vehicle in-person is going to be the best route for an accurate diagnosis.

Hope you find the source of that clunking.

Ashley Wilson

March 3, 2023 at 7:26 pmHi Josh,

In reading the information presented here, I’m a bit skeptical about a quote I was given. I was told both front sway bar links need to be replaced, and they gave me an estimated cost of nearly $500. What are your thoughts? Is this reasonable, or should I look elsewhere to get the problem fixed?

Josh Daniels • Post Author •

March 6, 2023 at 8:35 amHey Ashley,

That seems REALLY high.

There are some factors that could be at play here, but unless there are some pretty wild circumstances that quote sounds like a lot more than you should be paying.

Generally end links are not very expensive (less than $100 on average for a set) but for some vehicles or performance applications they could run $100-$200 for the set.

Since in the vast majority of cases the bar does not even have to be removed it’s hard to see a reason that replacing the front end links would take more than an hour. Most times it is a matter of unbolting each end of the link from the sway bar, removing the end link, and bolting on the new one. So unless the mechanic is charging $300-400 an hour the math doesn’t jive.

Again, without knowing the vehicle or the details it’s impossible to say for certain, but if one set of end links are the only thing being replaced and there is no other work going on simultaneously that quote seems unreasonably high.

Hope this was helpful and good luck getting the work sorted out!

LostInTransit

May 26, 2023 at 6:07 pmAgain, Josh and Suspension.com are on top of things. With the eventuality that a 28mm Hardrace sway bar will be installed on our Connect, we’re not to thrilled with the rubber bushings that come with the kit. Therefore when ordering the sway bar, we’ll also order the Energy Suspension 28mm Poly bushings and grease brackets that comes with the Energy Suspension kit.

Josh Daniels • Post Author •

May 31, 2023 at 7:22 amHey Lost,

Yeah, the biggest complaint with poly sway bar bushings is that they can squeak if they lack lubrication. Energy Suspension’s greaseable design makes fixing that problem a hassle free job so there’s really no reason to stick with the rubber bushings.

LostInTransit

June 13, 2023 at 3:45 amJust wanted to confirm that the 28mm bushings and hardware arrived Fri and we’re that much closer to getting the 28mm hardrace sway bar on the van. So, time for a little side trip to a new shop that’s invited us to check out their parts. Once we return we’ll order that hardrace sway bar. Plus we’ll prob go ahead and get those factory front coil springs.

Josh Daniels • Post Author •

June 13, 2023 at 9:44 amHey Lost,

Glad to hear those arrived without a hitch! Thanks for keeping us updated and we would love to see some pictures once you get the new sway bar installed.

LostInTransit

June 13, 2023 at 9:51 amJosh, just wanted to confirm. We need to use NON lithium grease on these new poly bushings? what would be the name of a particular brand we can locate. I need to make sure of this as the shop will need a grease gun specifically for our build.

Josh Daniels • Post Author •

June 13, 2023 at 3:35 pmHey Lost,

In our experience, and going by what poly bushing manufacturers use, a silicone based grease with a PTFE additive is your best option for proper bushing operation and longevity. If you want to read up more on the differences in different lubrication options you can check out our article about the best grease for polyurethane bushings where we dive pretty deep on the topic.

Most poly bushing manufacturers include a few small packets of grease which should be enough to get small jobs like sway bar bushings done. In most cases you should not need to re-lubricate the bushings for five years (or longer). The most common issue is squeaking which is indicative of a lack of grease between the bushing and the bar. Unless you have some other greaseable poly bushings a grease gun might be over the top since it would be several years at least before they need servicing, unless you are routinely burying the undercarriage in mud 🙂

We offer Prothane, Energy Suspension, and Daystar that would be suitable for poly bushings and you can check those out just to get an idea of what the manufacturers suggest.

LostInTransit

June 27, 2023 at 10:31 amUpdate: After 1 year of driving on the cheaply made Carquest end links, the failed early this morning and now we’ll have to replace them. Mind you the warranty ran out a few days ago and I was hoping to wait until we ordered the 28mm Hardrace sway bar then install the super-pro 300mm-345mm Volvo end links. But now it looks like we’ll have to go ahead and install the super-pro 300mm end links before we order the sway bar. However, this maybe a god send as we’ve measured the Carquest end links and they measure the same as the super-pro end links. I was hoping that the super-pro end links we a bit shorter. So instead we’re looking to cut at least 1/4 of an inch off both ended of the super-pro end links and reattach the ball joints. Just for reference, the Carquest end links measure roughly 12” from center to center. While the super-pro measure the same. When we cut a small amount of the main rod on these adjustable end links, this will shorten the end link to approx. 11 inches. Then we’ll install these newly modified end links onto the van. If successful, this should tighten up the front end of the van without compromising any components. Plus this could mean that we can retain the factory 24mm sway bar and may not have to order the 28mm Hardrace sway bar. All of this should take place within the next two weeks.

Josh Daniels • Post Author •

June 30, 2023 at 7:56 amHey Lost,

Sorry to hear those end links could not hold on just a little longer. If you are looking to shorten those end links by an inch then cutting around a half inch on each side should do the trick and hopefully there are no unforeseen issues. Just a friendly reminder that any modifications to the end links will void any warranty so be sure to measure thrice and cut once 🙂

If you email us some pictures we can attach them to the post. Good luck with the modification and install!

LostInTransit

June 27, 2023 at 10:40 amAlong with my end links modifications, I wanted to say that We’ve reported an issue to Rockauto, Summitracing, Duraklast, Moog & Mevotech. We tested the duralast, moog and mevotch heavy duty end links on our 2020 connect and found that all though the links attached correctly, there’s zero clearance with how all three of these links are designed. Deep marring was seen on our firewall and subframe within the front wheel well. We again reported this issue to all those listed above and the only one who responded to our concerns was Dorman products. They said that they would forward our findings to their tech team for evaluation. Dorman Products sent us a set of tuner lugs for the van. as for the rest of those we’ve contacted, they have yet to edit their sites based on our findings even after sending them images of the links on our van that caused damaged to our subframe. I urge anyone who has a Connect NOT to buy the Duralast, Moog or Mechotech heavy duty end links because our test proved these links will not articulate correctly within the wheel well of a 2020 Connect. So be warned as those sites listed above still have these links as being suitable for the 2020 Connect. which is not the case.

Josh Daniels • Post Author •

June 30, 2023 at 8:10 amInteresting. So is it the length of the endlink itself that seems to be causing this problem or the length of the bolts on the ends? Looking at the Moog site they have a note that the front sway bar links are “pending obsolescence” so it seems like they may know that there is a problem?

Glad you were able to catch that and let everyone know to be on the lookout for end link clearance in their Connects!

LostInTransit

June 30, 2023 at 10:04 amJosh, the issues (according to Dorman Products Spokesman) is that the ball heads on these heavy duty end links are too large because one is able to grease these ball joint when and if needed. The other links like the Carquest vers do not have these grease fitting mounted on them. thus reducing the size of the ball joint and hardware surrounding the ball joint. In one instance while driving with the set up, the three mentioned end links physically connected the same as any other end link, yet when places in full articulation, turning up and down travel etc the ball joints hardware/ends made contact with the subframe and firewall area. Also, at one point while turning into a parking lot, the drivers side end link because lodged between the coil spring and subframe causing the van to handle erratically.

Josh Daniels • Post Author •

July 5, 2023 at 8:55 amHey Lost,

Sometimes the zerk fitting on greasable joints can cause problems like this. One option is to remove the zerk fittings (but hang onto them) and plug the hole in the joint, then reinstall the fittings when it’s time to add some lubrication. This can be a hassle if you are greasing those joints often, but it will reduce the footprint of those end links and still allow for lubrication whenever it is needed.

LostInTransit

June 30, 2023 at 3:51 pmGreat news, the shop just handed me the freshly cut sway bar end link rods. the cut a little more than we wanted them to. We’re able to make adjustments to these links via the ball joint threads and the threaded hex nut located on the ball joints. We’ve test fit the ball joints on each end and and at it’s lowest setting measure 10.75 inches. So in about 1 week time, we’ll take the van over to the shop and have them install these gifted/modified Super-Pro end links on the van. This needs to be done before we leave for our pre-fall travel, Plus we’ve selected a few very challenging roads to put the van though it’s paces. Thanks to Josh and those at Suspension.com for their help, but we’re not done yet.

Josh Daniels • Post Author •

July 5, 2023 at 9:02 amHey Lost,

Glad to hear those cut end links are working out! SuperPro manufacturers some high quality end links so I imagine they will perform really well on those challenging roads. Thanks for the update!

LostInTransit

July 21, 2023 at 12:55 pmJosh thanks for being on top of this. However, the shop tech who was handing our installation of the end links retired and we were left without someone to install these. But I should be able to locate someone very soon. I’m here to say to get your thoughts on what we’ve learn and seen online about the angle of the sway bar is important. For instance, one site shows the sway bar as being level or perpendicular to the vehicle’s frame as the optimal position of the sway abr. Yet it does show that the sway bar with a shortened end link can or could be no less than 10° above level and no more that 20° below level. Currently the Carquest end link being too long did not offer us a very tight front end. The end link ended up being almost 12 3/4 which is too long. so installing the 10.75 or 11.00 end links should bring the sway bar up to level or just above level. Correct?

Josh Daniels • Post Author •

July 28, 2023 at 8:00 amHey Lost,

It’s difficult to give an accurate assessment without physically looking at the vehicle, but when it comes to sway bar positioning the “optimal” option is going to take a back seat to the dictates of the space that is available. This is why even though the most efficient shape for a sway bar is a straight bar going into 90 degree arms there are usually several extra bends.

In any case, the shorter the end link, the stiffer the twist of the arm and the tighter the handling and body roll will feel.

Good luck finding a replacement mechanic!

LostInTransit

July 31, 2023 at 11:12 amJosh, We had to drive 3 hours to our tire shop, but while there I got the support and suggestions from the shop manager. We both looked at the current end links and found that even though they seem to be too long, the sway bar is rest at a 10° angle. Acceptable angle range is 10° above, in the middle or 20° below level. So adjusting the superpro end links to approx. 11.25 or 11.50 would bring the sway bar back up to a respectable level. We found another shop, but seeing how we took a trip last week and used all the money, we’ll have to wait a few more weeks to get the new links installed.

Josh Daniels • Post Author •

August 7, 2023 at 7:33 amHey Lost,

Glad you were able to get that sway bar angle squared away! The adjustability available on most of Superpro’s end links makes those small tuning touches very simple. The saga continues!

LostInTransit

August 11, 2023 at 11:16 amThis just in CONFIRMED FIT of the 300mm-345mm Super-pro end links on a 2019-2023 Ford transit Connect. However, Most parts sites like either a 11.9 inch end link or a 13.x inch end link for our van. But checking the van on level ground, shows that the end link is below level. We had the shop cut approx 1/4 of an inch off each end of the rods.. then reattached the ball joints. We just had the modified 11.50 end links installed on the van and the sway bar completely level. Although we’ve drive around town, I can tell a small improvement in the stiffness and handling. But we still need an alignment check as we hit some very hard roads 2 weeks ago. The van is pulling to the right. So if someone wants to install the super-pro 300mm end links they will fit. But modify the links from 11.9 to 11.5 will increase the handling of you van. Currently I can’t say we’re going to install the 28mm hardrace sway bar.. but we’re about 85% sure we will. So thanks to the anonymous vendor on Amazon who donated these end links on behalf of Zeder Corp

Josh Daniels • Post Author •

August 18, 2023 at 11:28 amHey Lost,

Glad to hear the modified end links seem to be working well! An alignment would be a good idea before any big trips with all the work you guys are doing. Good luck with the next leg of the project!

ROBERT

October 15, 2023 at 5:24 pmI bought the front sway bar bushing set for my 2003 suburban. How far do I tighten the nut and “crush” the bushing on the sway bar link parts?

Josh Daniels • Post Author •

October 18, 2023 at 8:51 amHey Robert,

You should tighten the end links to a “snug” amount but not to the point that you misshape the grommets. Rubber grommets will be a lot more pliable and can squeeze a bit when being tightened down while poly grommets will provide more resistance. In either case they should be tightened enough to prevent looseness of the sway bar but not so much that they bind.

Hope this was helpful.