How To Grease Tie Rod Ends

UPDATED: August 2019

A question we constantly get at DST is “How do I grease my Tie Rod Ends?” Some tie rod ends come with a grease zerk fitting installed and some are sealed from the factory with no easy avenue for lubrication. Here we will share some detailed instructions about how to grease your tie rod ends with or without a zerk fitting, what grease you should use, and how to troubleshoot potential problems.

Grease is cheap compared to your vehicle so extending the life of the parts that make up your car with some routine lubrication is a no brainer, but lubricating a sealed tie rod end is more of a temporary measure to breathe some life into a dry, groaning part.

Table of Contents

Grease or Replace?

If your tie rod ends are clunking and upon inspection you find that they are loose then they are probably too far gone. Grease is good for noise and maintenance but it will not make a failed part function properly. If you do need to replace your tie rod end we offer Moog outer and inner tie rod ends for most makes and models.

What is the Best Grease for Tie Rod Ends?

Basically any grease rated “GC-LB” by the NLGI (National Lubricating Grease Institute) is graded to work for all your chassis lubrication needs, including tie rod ends. Lucas X-tra Heavy Duty Grease or Marine Grease are designed to last in extreme environments and keep your tie rod ends lubricated and operating smoothly. While that may seem like overkill, using quality tie rod end grease is much cheaper than a replacing a tie rod end. Also we sell these lubricants 🙂

Lucas X-tra Heavy Duty Grease is designed for, you guessed it, heavy duty vehicles like those used in farm and construction settings. This is quality lithium based lubricant with additives that make it more resistant to the elements and give it more sticking power, boasts an effective lifespan 4 times longer than regular grease. Great option for the tie rod ends on any vehicle but really shines in off-road or fleet vehicles, a tough commute, and adverse seasonal weather.

Lucas Marine Grease uses calcium sulfonate thickeners and is designed specifically with water-craft in mind but it works wonders in vehicles that are consistently exposed to water, slush, snow, and road salt. This grease also provides above average protection against corrosion and rust making it a perfect fit for a vehicle that spends a lot of time in a coastal climate where salt in the environment can drastically shorten the life of chassis components. If your climate is tropical, coastal, or snowy then this grease will serve you well and very likely extend the life of your tie rod end compared to regular grease.

Pick your Tie Rod End style for lubrication instructions:

How to Grease Tie Rod Ends with Zerk Fittings

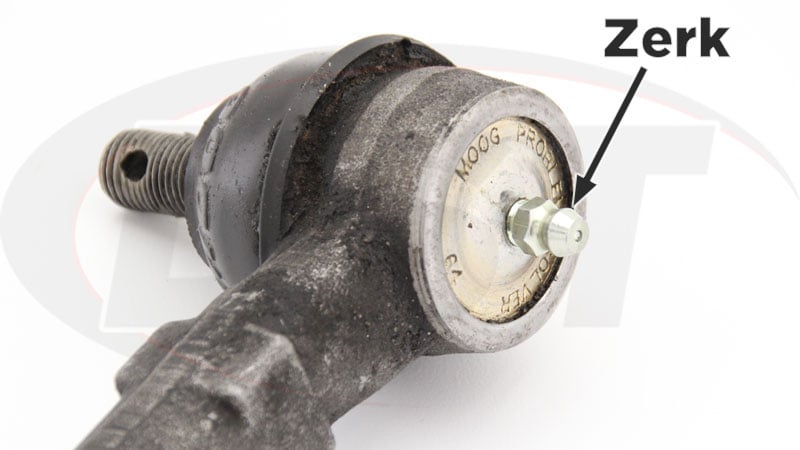

Tie rod ends have an articulating metal stud that needs grease to keep your steering smooth. A zerk fitting makes this process very simple and gives you an easy way to keep those tie rod ends in good shape.

The general consensus is to grease these parts when its time for your oil change, but garages do not always do this. Also if a lot of water and grime are thrown around under your car you might want to lubricate your tie rod ends more often. Now lets take a look at how to grease those tie rod ends.

Tools:

-

A Grease Gun – A powered grease gun might be a little faster but you have a much better chance of blowing a seal on your tie-rod end with one. We suggest a manually powered gun.

-

Grease – Always use the suggested grease or a Heavy Duty Lithium Synthetic or Marine grease. These types of grease handle the stress of constant use and will repel water.

-

Flexible Hose – Grease zerk fittings on a tie rod end make the lubrication process much easier but the angles of some zerks are almost impossible to reach without a flexible hose attachment.

-

Rag – Don’t laugh. Cleaning the zerk and wiping away excess grease is an important part of the process. This will keep dirt and debris from entering the joint and collecting in excess grease later.

DST offers these tools (minus the rag) in a Grease Gun Combo for your convenience.

Instructions:

1.

First, inspect the dust boot for tears or leaks. If you find any then you should replace the dust boot to prevent contaminates from enetering the joint and you might consider replacing the tie rod end if there is any looseness or vertical movement.

2.

Now, use the rag to clean the zerk to avoid any contaminates following the grease inside. You should see bright shiny metal before you attach the grease gun. If the zerk is rusted or corroded beyond simple rag cleaning you can use something stronger or replace the grease zerk.

3.

Next, attach the grease gun to the zerk. Position the nozzle squarely over the zerk and press down until you feel the “snap” of the nozzle grabbing the zerk. If the coupler on your grease gun is adjustable you can unscrew it a small amount to loosen the jaws to make the connection easier, just remember to tighten it back down before pumping.

* If the nozzle hasn’t connected to the zerk then grease will ooze from between the zerk and the grease gun.

4.

Then, watch the dust boot and give the grease gun a few good pumps and STOP if you see the boot begin to swell. It is best not to keep greasing once you see the boot swell since the seal that holds that grease in the tie rod end can be compromised if too much pressure is applied. If the seal breaks you will be replacing that part sooner than later.

* Some tie rod ends have a grease relief valve that will allow old grease to safely exit the tie rod end without compromising the seal.

5.

Detach the coupler from the fitting. This can be difficult but you can loosen the jaws again if you have an adjustable coupler.

6.

Lastly, clean off any excess grease from the zerk and dust boot. Drive the car around the block and check for leakage.

* If you have a rough commute or hit the trails on the weekend then take your vehicle out on some similar terrain and check the joints afterward.

Trouble Shooting:

How to clear a plugged grease zerk fitting

Few things are more frustrating than knowing a job is going to be a piece of cake and then have something go wrong. You expect the lubrication process to be short and sweet but if grease is oozing out of every connection on your gun when you start pumping then something is definitely off.

You can remove the zerk and try to pump grease through it as a first step but if nothing comes out then your zerk is probably plugged with old hardened grease. Here we will show you a simple way to clear that zerk fitting.

First, remove the zerk fitting and attach it to your grease gun.

Try pumping some grease through the zerk and this will sometimes push hardened grease out of the fitting.

If there is still no grease moving you can use a propane torch to heat up the zerk. This will boil out any hardened grease that is plugging the grease fitting.

Now just reinstall the zerk and you should be able to get some grease into your part.

Now we will look at some other problems that can come up when greasing a zerk fitting.

- Make sure your grease gun is fully connected to the zerk. If you’re sure it’s connected well and grease is still escaping from around the zerk fitting make sure the coupler is as flush as possible against the zerk.

- Keep some pressure on the coupler to make sure the seal is tight.

- NO POWERED GREASE GUNS. You lose the ability to “feel” when the joint begins to resist the pressure and there is no better way to blow a seal than a powered grease gun.

- Grease zerk fittings can be replaced with 45 or 90 degree angle fittings, making present and future maintenance easier in terminally hard to reach spots.

And that is how you lubricate a tie-rod end. Pretty simple right? If you want to start tackling this maintenance project at home, DST offers a Grease Gun Combo that includes all the tools we used in this article. If you want to take on a similar maintenance project check out our post on how to grease ball joints with a zerk fitting.

Does anyone have any advice that we didn’t mention? Have you had any experiences with greasing a tie-rod end that could be helpful to a beginner? Please leave us some comments or questions in the comments section at the bottom of the page or if you have questions you can contact the customer service folks at suspension.com. Good luck!

How to Grease Tie Rod Ends without Zerk Fittings

Theoretically, sealed tie-rod ends come from the factory with sufficient grease and are buttoned up tight to keep contaminates out, but if you want to refresh the lubricant in your tie-rod ends you can use a grease gun needle attachment to get past the dust boot and pump some grease into that part. A lot of people have different opinions about whether or not this method actually gets any grease where it’s supposed to go, but if your tie-rod ends are making noises like they need some grease you can quiet them down using a grease zerk needle.

Tools:

- A Grease Zerk Needle Adapter – A needle fitted with a grease zerk can penetrate the dust boot and introduce grease inside the tie rod.

- A Grease Gun – A manually powered grease gun will let you decide how much grease goes into the tie rod and let you know when it is getting full.

- Grease – You should use the OEM suggested grease or a Heavy Duty Lithium Synthetic or Marine grease. These are perfect for automotive applications and will last longer than other types.

- Flexible Hose – This is not necessarily a requirement, but it makes the job about 10 times easier. Save yourself some frustration and use a flex hose.

- Rag – To clean the zerk and wipe away excess grease. This will A) keep dirt and debris from collecting around the tie rod end and B) allow any leakage to much easier to spot later.

You can get all of these tools (find your own rag) in a Grease Gun Combo from DST.

Instructions:

1.

With any part protected by a dust boot, you should always inspect the boot. If it is torn or possibly even gone then you need to replace the dust boot and you should consider replacing the entire tie-rod end. Contaminates may have already worked their way into the bearing, wearing the smooth surfaces down and setting it up for failure.

2.

Clean the tie rod end and boot so you can see what is going on with the seal when you begin pumping grease into it.

3.

Attach the grease zerk needle adapter to the grease gun and this can be tricky so we advise caution. If your coupler is adjustable remember to tighten the nozzle once the needle is on or grease will ooze out from between the needle and grease gun.

* If you are not careful you could easily be using the rag to wipe up blood instead of grease. If you have an adjustable coupler try loosening the clasping mechanism to make the process easier.

4.

Insert the needle into the boot close to where the boot meets the housing to make sure more new grease is getting to the bearing and old grease is being pushed away.

5.

Watch the dust boot and pump slowly, stopping once the boot swells. There are some different schools of thoughts here; some say to keep pumping until grease oozes out from under the edges of the boot while others believe once the boot starts to swell you should stop pumping. We suggest stopping early since maintaining the integrity of the boot is important.

6.

Remove the needle and clean off any excess grease. There probably won’t be much excess grease but if there is wiping it away will keep dust and debris from collecting on that extra grease and allow a quicker diagnosis of future problems, like a leaky dust boot or failing seal.

7.

Lastly, drive the vehicle around the block or down a dirt road if that’s your daily commute. Once you’re back in the driveway take a look at those wiped down joints and see if any grease is leaking. This could mean a busted seal, but if everything looks and sounds in order then congratulations, you’ve just “greased” the un-greasable.

Trouble Shooting:

- NO POWERED GREASE GUNS. We’re trying for a feather touch and a powered grease gun can bull rush right through that dust boot without a backward glance. Stick with the hand pump and call it exercise.

- Most grease guns come with an adjustable coupler these days but if yours does not then getting one will make any grease maintenance much easier, especially trying to take a needle off of your grease gun.

- Make sure the needle is clean. We’re trying to keep the contaminates out.

Weather Stripping Adhesive Patch

Weather stripping adhesive can be used to cover the needle hole in the dust boot if you’re worried that water or contaminates might make their way through to the smooth working surface of the tie rod end. This adhesive forms a flexible, water-proof seal that is resistant to the elements. Simply cover the area with the adhesive and be sure to follow the instructions and safety precautions.

So, if you want to try and breath a little bit of life into those sealed tie rod ends we offer a Grease Gun Combo which contains all the tools used in this how-to. To see another suspension maintenance project take a look at our how-to about greasing ball joints without a zerk fitting.

Has anyone used this method to grease a sealed tie rod end? Are there any helpful tips and tricks that you’ve discovered? If you have any questions leave them in the comments section below or contact the customer service experts at suspension.com. Good luck!

Quick word about Bad Tie Rod Ends

If you’re experiencing play in your steering or a shaking steering wheel then you may have a tie rod end that is already worn down and while lubrication may buy it some time, eventually that part will fail completely. A tie rod end that is loose or has vertical movement needs to be replaced. Moog offers premium inner and outer tie rod ends for most makes and models, and they usually come with a grease zerk fittings for easy maintenance among other advantages over OEM replacements.

Greg wherland

May 22, 2017 at 2:27 pmDoes using the needle take away from the integrity of the boot? And how many times can you grease it that way?

Josh Daniels • Post Author •

May 24, 2017 at 1:59 pmGreat questions Greg,

1) The simple answer is; Yes. Especially with hard use like off-roading or poor road conditions your tie rods will be moving around a lot and this will cause any breech of the boot to grow over time. You can seal the hole with a weather stripping adhesive, which will reseal the boot and keep grease in and debris out. If the part is just groaning and there are no other symptoms and you think you can get some good miles out of the tie rod end you could replace the stock rubber boot with a universal polyurethane dust boot that will definitely out-last the tie rod end.

2) I would not suggest using this greasing method more than once or twice. The amount of grease that will actually make its way into the ball and bearing of the tie rod end is unknown, but probably not much. It will likely fix any noises coming from your tie rod end but it won’t fix a part that is exhibiting symptoms of failure. In that case you’re going to have to replace the tie rod to fix those problems.

So, using the weather stripping adhesive will plug the hole and maintain the boot’s integrity, but this isn’t really a routine maintenance method. Just a way to stop a squeaky tie rod end or get a little more life out of a part that is on its way out.

Is anyone totally opposed to this method? Even with the hole being sealed after greasing?

Thanks for the question Greg.

Earl Bailey

September 29, 2017 at 3:46 pmI use a grease needle whenever there is no zerk.

In fact I once had a U-joint that I could not get a grease gun to fit down into the zerk.

To grease it I had to remove the drive shaft from the rear axle. Remove the two exposed bearing caps. Then with a larger needle I pumped fresh grease into the U-joint.

I also added a small dab of grease to the caps themselves in hopes that may force a little bit of gresse into the other caps.

It did seem to work.

Josh Daniels • Post Author •

October 2, 2017 at 7:40 amHey Earl,

Good thinking using the needle to get that hard to reach U joint. Sometimes it takes ingenuity to get maintenance done on some of those parts.

If your U joint has a straight zerk, and you think it would help, you might replace that zerk fitting with a 45° or 90° angle zerk. That could give you a better angle to attach the grease gun next time.

Thanks for the information and keep up the good maintenance!

Dan

January 30, 2018 at 1:04 pmWhat grease type should be used, and shouldn’t it be silicone grease, since regular grease will eat up the boot?

Josh Daniels • Post Author •

February 2, 2018 at 12:26 pmHey Dan,

Great question and one that has a lot of misinformation associated with it. The answer to the first part is pretty straight forward since the NLGI (National Lubricating Greases Institute) has a rating system that lets people know what a particular grease can be used for.

If the grease rating contains the letters “LB” then the grease has been rated for chassis components and parts such as ball joints, tie rod ends, u-joints, etc. Wheel and axle bearing grease will have the “GC” designation and something that contains both “GC-LB” can be used in either situation. The number at the bottom is the consistency rating that ranges from “000” to “6” with the low end being the most liquid-like and the highest being the most solid.

The boot question is a little more difficult since not all dust boots are the same. Many “rubber” dust boots are not actually natural rubber but a polymer like Nitrile or Neoprene. They’re similar materials but one of the big differences is the resistance to petroleum based products which makes the polymers a more suitable material for a dust boot. That said, without asking the manufacturer what the boot for a specific part number is made of you don’t really know what you’re getting. I just spoke with the Garage Gurus and they assured me that any chassis rated grease is not going to have adverse effects on Moog dust boots, but I can’t vouch for this being an industry standard.

If you’re worried about the rubber boots breaking down you could try a universal polyurethane dust boot. Polyurethane is much more resistant to wear and other elements, such as heat or road salt that can break down rubber, and will almost certainly last the life of your vehicle.

Thanks for the question Dan. Hope this was helpful.

John

February 9, 2019 at 6:56 amThis was the main thing I was looking for here. Thanks for the information. Great article overall.

Michael Foley

April 27, 2018 at 12:44 amThanks for this! Very helpful

Josh Daniels • Post Author •

May 1, 2018 at 3:59 pmThanks Mike,

That’s what we’re here for 🙂

Robert R. Scott III

October 5, 2020 at 7:42 amGreat article! I just bought 2 different brand tie-rod ends… (availability) One has zerk other didn’t. The one with no zerk seems empty of grease (brand new)… should I use needle method? Just feels like I shouldn’t because brand new, but also feels odd having it on without a full boot of grease.

There are no noises or play on either after installing and test drive.

Josh Daniels • Post Author •

October 6, 2020 at 8:15 amHey Robert,

Short version: Maintaining the integrity of a brand new boot is more important than stuffing extra grease into a joint that is almost certainly greased at the factory.

Generally a ball joint or tie rod end that is sealed without a zerk fitting has already been lubricated. Even if the boot is not full of grease the metal surfaces of the joint are covered and that is what you really want. As long as the tie rod end isn’t giving a metal on metal grinding or squeaking sound then it likely does not need grease.

Using the needle is is a method to get a little more life out of a joint that has begun to make some troubling noises and will probably need to be replaced in the near future, not to top off a brand new tie rod end (which is fine, by the way, if there is a grease zerk fitting).

All of this said, if you are putting an unusually high volume of miles on your vehicle, routinely taking fast hard turns, or driving in icy or coastal climate then the demands on your tie rod ends and the environmental factors can accelerate their wear. In those cases it is advisable to have a tie rod end that can be maintained with grease regularly.

Thanks for the question and hope this was helpful.

Brian

April 9, 2022 at 6:33 pmIs there any instance when an outer tie rod with no zerk should NOT be greased?

Josh Daniels • Post Author •

April 12, 2022 at 7:17 amHey Brian,

Absolutes are pretty tricky, but since greasing a sealed tie rod end is really a measure of last resort to quiet down and prolong the life of a tie rod end that is already on its way out its hard to see any harm in it. Knowing when to give it up and just get a replacement is the key.

matt

August 19, 2022 at 2:06 pmwhy not drill and tap it and put a grease zerk in and wont damage boot

Josh Daniels • Post Author •

August 22, 2022 at 8:35 amHey Matt,

Tapping the rod end and installing a grease zerk can be accomplished by experienced grease monkeys but there are two reasons that most folk should not try it.

1) You can pretty easily damage the ball of the stud by drilling into the housing which would mean buying a new rod end and 2) Most ends that do not have a grease zerk are designed as a closed system and do not cooperate when trying to get old grease out or new grease in so its a lot of risk without much reward.

If you are feeling confident or lucky you can give it a shot, but its not something we suggest. If you are worried about damaging the dust boot it would be a much simpler process to just replace it with a universal poly boot, if there is one that fits your required dimensions.

Thanks for the comment Matt and have a good one.